A crisis is brewing in Patiala Loco Works

Failure of locomotives in field is increasing and quality is falling. It is important to note that CLW which owns rights over change of design, should incorporate CAD in day-today working instead of using it only for show casing in VIP visits

At the heart again is shell of the locomotives-an item which has seen serious fluctuation of prices and serious clash between the vendors-winners being those from Kolkata. It is reported that parts of certain shells supplied by approved sources to Patiala Locomotive Works (#PLW) were found to have been made with older specified material. The matter was complained to vigilance-this led to unprecedented logjam-what do you do when several of part-I sources make same mistake.

It is alleged that a committee of #PHODs was nominated to find a way out. The recommendation has been given and it appears that these #vendors who did not change the grade of #steel will be imposed a fine.

But what is root-cause of the issue?

Chittaranjan Locomotive Works (#CLW), a unit located in West Bengal is considered to be the original electric locomotive factory of India. This unit started manufacturing #ABB technology based 6000 hp #Passenger and #Freight locomotives in late 1990s. All the designs are held by CLW. However, problem with CLW is the poor design discipline, which means that CLW does not maintain proper documentation of its drawings and repeated photocopying has led to loss of several important details in field.

As is well known, typically, drawings are made in sets-where there is a parent assembly and then part drawings. A well maintained Production Unit like Integral Coach Factory (#ICF) and Banaras Locomotive Works (#BLW) uses advanced #CAD software which ensures that a change made in one drawing, gets reflected in all linked drawings.

Due to manual drawing management, it is said that CLW changed grade of steel of several members in parent drawing but child parts were not updated.

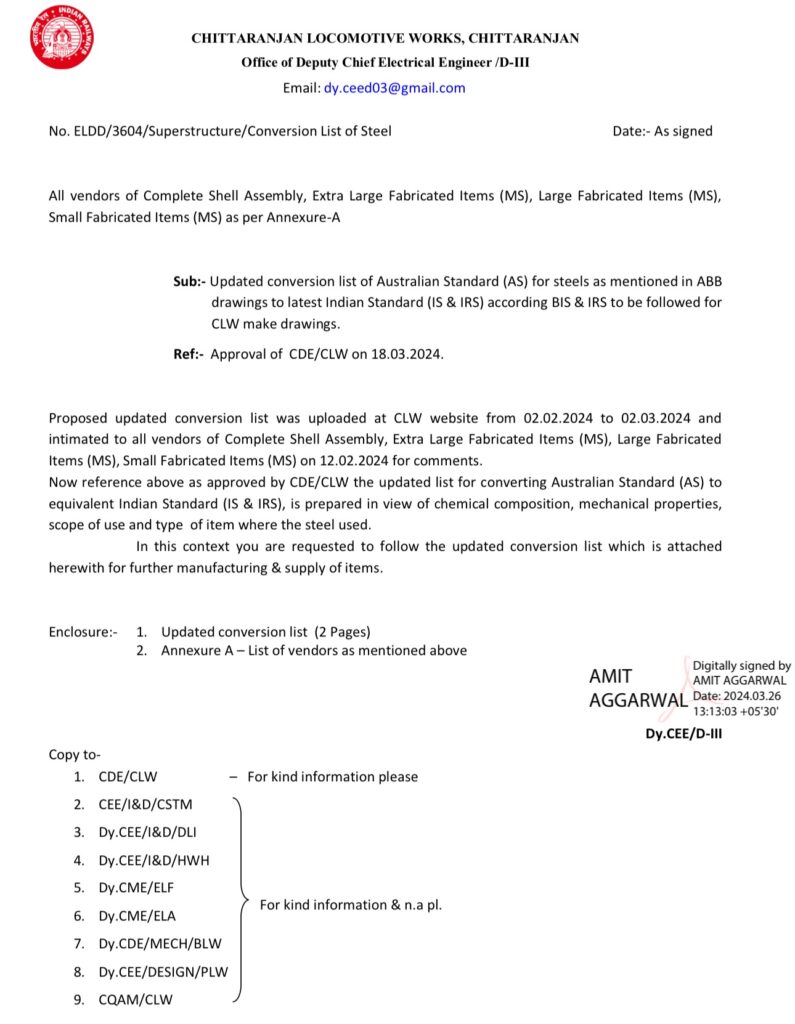

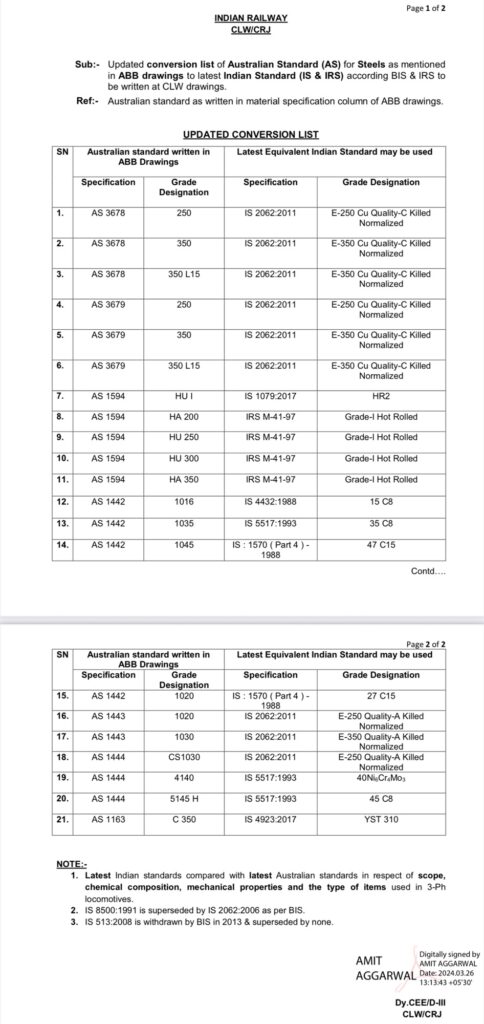

It is learnt that CLW wanted to introduce weather resistant grades of steel, so after almost 24 years of producing #locomotive shells, on 23 March 2024, CLW issued a letter which caused this confusion.

Availability and cost of steel has been highly fluctuating. It is well known that all steel sections are rolled in a certain minimum order quantity.

It is learnt that roof and side walls were kept as per older grade as they are #IRSM 41 grade which is weather resistant. But problem with this grade is that this is not available in thicker sections. So rest other steels were changed to a different grade which is copper bearing known as IS 2062 E250/350 CuC.

It is learnt that three of the manufacturers used all plates as per new grade, while two manufacturers used brackets and non-traction force bearing mounts of older material. There is reportedly only one #vendor who used all types of steel of new grade. However, it is alleged that even here the material is not CuC but CuB or CuA, as there are no vendors who roll IS 2062 E250 CuC for brackets etc. It is further learnt that additional cost of new grade versus older grade is just Rs. 3.50 per kg. For a product cost Rs. 70 lakhs, the saving would have been less than Rs. 5,000 in brackets etc.

This confusion has stalled the production of locomotives at PLW apart from several vigilance complaints.

Way Forward

Address root of the problem. Already failure of locomotives in field is increasing and quality is falling. It is important to note that CLW which owns rights over change of design, should incorporate CAD in day-today working instead of using it only for show casing in VIP visits.

Whenever design changes are made, they should be done in a manner that all #vendors understand them. That there is a confusion is amply corroborated by the fact that these shells passed stage inspections. Making a change which ends up rejecting all vendors is not practical.

Further, locomotive items are now attracting vigilance cases. This dampens competent officers to tighten screws on erring vendors. There is a #nexus in #inspection and in #design of CLW which needs to be tackled. Why would competent officers like to be posted there? This needs to be answered. CLW must adopt modern work practices.

Also, #RailwayBoard must counsel #Vigilance that they should not be gamed by the competing vendors. In case senior officers take a decision, railway board must support them. Unless CLW is reformed production of electric locomotives at BLW and PLW will remain problematic.

There is need to club tenders of same item which are floated separately by CLW, BLW and PLW. This will reduce prices and help in faster decisions.