Price Variation Clause & Long Term Contracts

Given the Railways’ own data and history suggesting gradual real-term reduction in costs over time does it make sense to award long term manufacturing and supply contracts with liberal Price Variation Clauses?

Long-Term-Contracts have often been preferred as a smooth path to #goods and #services. A long-term #contract is promoted as a way to providing continuity to the buyer and the seller. The #buyer locks-in a steady price and assured supplies. The #seller gets assured business guarantees based upon which he can raise capital, invest in #machinery and #plant, hire #manpower and #train them and enter into similar long-term contracts with his own supply-chain. The whole arrangement looks like a win-win game for all. But is what appears logical and rational really so? Let’s take a look-

Indian Railways’ #Production-Units, the factories that make #Passenger #coaches and #locomotives, are some of the lowest cost producers of #rolling-stock in the world. It is often overlooked that they are also among the most innovative and efficient of all. The Integral Coach Factory (#ICF) Chennai, for example, has designed and manufactured at least seventy types of passenger coaches ranging from 75kmph non-AC third class to 180kmph Vande Bharat Trains. It has made coaches in mild steel to stainless steel and exported to over a dozen countries. It has also made mobile missile-launchers for the armed forces. Likewise, our locomotive factories have designed and manufactured dozens of types of #diesel and #electric locomotives.

What is not known is that the cost of #production of these #coaches and #locomotives have remained more or less constant at current value and has actually dropped significantly if adjusted for inflation – up to 30 and 40%. How has that been possible?

Manufacture of a complex product is infinitely amenable to innovations that bring about production efficiencies. Unlike a simple #procurement such as hiring #housekeeping manpower or procurement of say #minerals or #raw-material, the cost of which is driven by the #WPI or #CPI, manufacturing creates its own efficiencies to not only counter the rise in inputs costs of manpower and raw material but bring about a much larger economy.

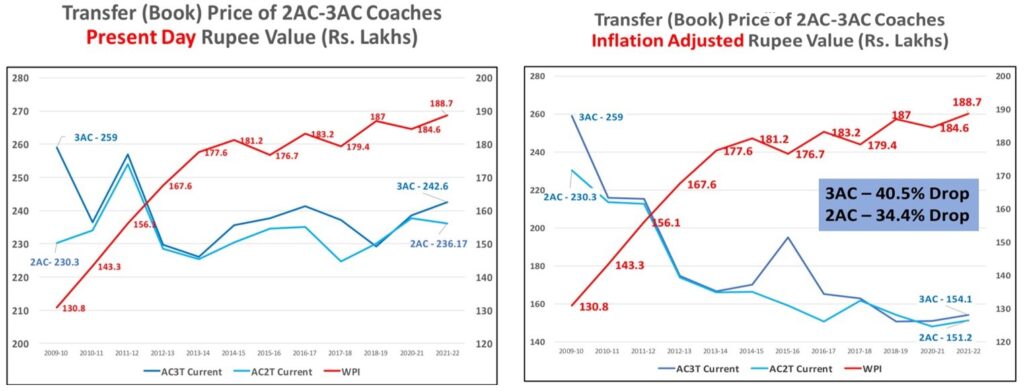

This is not mere theoretical treatise, nor is it a utopian lesson from an academician in a management school. This is what #IndianRailways have actively practised and achieved year after year. Take a look at the two #charts.

This is only a sample, albeit a large one, that spans twelve years and tens of thousands of data points. Official data from the Ministry of Railways from 2010 to 2022 reveals the following incredible facts:

- The book transfer price (basically the cost of production) of 2AC coaches have remained nearly constant in this period.

- Adjusted for inflation the unit manufacturing cost of 2AC coaches has dropped sharply from 2.3 Crore to 1.5 Crores, a 34.4% drop.

- Figures for 3AC coaches indicate a nearly constant cost of production at current value of rupee and a drop from 2.5 Crores to 1.5 Crores when adjusted for inflation, a reduction of 40.4%.

- Similar figures exist for locomotives but have not been mentioned for the sake of brevity.

These figures should be compared with the WPI in the same period, which has increased from 138.8 to 188.7, in increase of 44%! If Indian Railways’ Production Units had not reduced costs of production, a 2AC Coach would cost 3.4 Crores today, not 1.5 Crores. Likewise, a 3AC Coach would cost 3.6 Crores. Agreed, the Price Variation Clause (#PVC) may not have the same rate as that of the #WPI, but #RBI indices for various materials and parts closely follow it.

I have worked in production units of locomotives and coaches and have not only seen first-hand how this has been achieved but have also been a participant in such exercises. Some of the major factors that have brought about a steady improvement in efficiencies and reduction in costs are given hereunder. The list is by no means comprehensive:

- Improved processes – better welding techniques, high productivity machine tools, quick drying paints.

- Automation – CNC, online inspection.

- Time and Method Study – Good old Time and Method Study techniques improve processes and reduce time-taken on elemental levels.

- Modern Quality Systems – Process Control, Templates, Check sheets. Reduced Rejections, Reduced Wastage, and Negligible Rework

- Training – Technical, Motivational, Teamworking.

- Energy Efficiency – Energy Efficient Motors, Lights, Invertor Based Equipment.

- Better Logistics and Transportation – Development of Vendors in Geographical proximity, which also provides employment to locals.

- Inventory Control – High Value parts and assemblies often have just about a week’s stock.

- Alternate Materials – Fabricated vs. Cast, Plastics vs. Metals, Composites.

- Periodical Price Discovery – This has been the single largest factor in cost reduction. Unlike long term contracts, which common sense suggests should bring about economy, each procurement cycle brings in new players and higher economies. #Competition in each procurement #tender encourages our #vendors to reduce costs in their own systems. New entrants, even if lower priced, have to go through an elaborate circle of trial, intensive inspection, and approval.

Given the #Railways’ own data and history suggesting gradual real-term reduction in costs over time does it make sense to award long term manufacturing and supply #contracts with liberal Price Variation Clauses? This at best locks-in inefficiencies and at worst discourages innovation and benefits #contractors unduly at the cost of public money.

Courtesy: “Price Variation Clause & Long Term Contracts”